Streamline Your Operations and Drive Efficiency:

Expert Process Improvement Services

Are your processes costing you time and money? Unmanaged processes lead to inefficiencies, waste, and suboptimal results. I help organizations optimize their operations through proven process improvement methodologies.

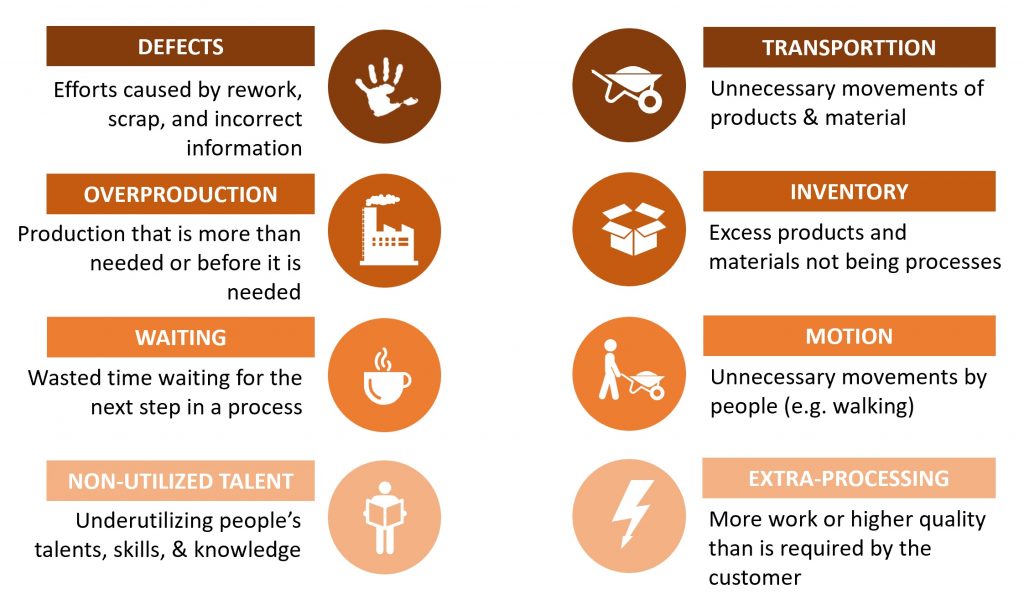

Identify and Eliminate Waste

Uncover hidden inefficiencies with the “8 wastes” framework and transform your processes for peak performance.

Proven Results: Real-World Examples

- Increased efficiency in Forex trading in Switzerland

Automating a process by rolling out a self-service tool for end clients looked like an efficiency win until a statistical analysis proved that human FX traders are able to deliver more value

- Streamlined sourcing process and local sourcing organisation in European locations

Part-time and uncoordinated supply management personnel were unable to align sourcing decisions with headoffice. By pooling purchases and creating synergies, significant cost savings were made.

- Improved resource allocation for payments processing in Singapore through better monitoring

Through meticulous time capturing of tasks, task duplications and waiting time could be identified that led to an eventual performance increase of 100%.

- Reduced client onboarding time in Microfinance Bank in Tanzania

Following the account opening process steps, some debilitating factors emerged that – when removed – helped clients to open accounts 4 times faster.

- Proposed more replication efficiency of microinsurance product implementations in MENA region

After 4 successful implementations and many more in the pipeline, the product team provided their insights which led to opportunities to cut the future implementation time in half and save 25% costs.

- Reduced time to loan disbursement for Microfinance institution in Egypt

The rollout of a new core banking system replaced a paper-based process and cut the previous loan application time almost in half. Yet the goal was to improve the time even more to 25% of the initial duration. After analyzing the approval process steps, a roadmap was proposed to reach the ambitious target over time.

- Reduced time to loan approval for Private Bank in Liechtenstein

By digitalising the loan application and loan approval workflow, the loan processing time was reduced by 85%. This was achieved by implementing the bank-side workflow with a low-code tool and without any automated interfaces. The time reduction was achieved by allowing approvers to act in parallel and use smartphones for the digital task

My Services:

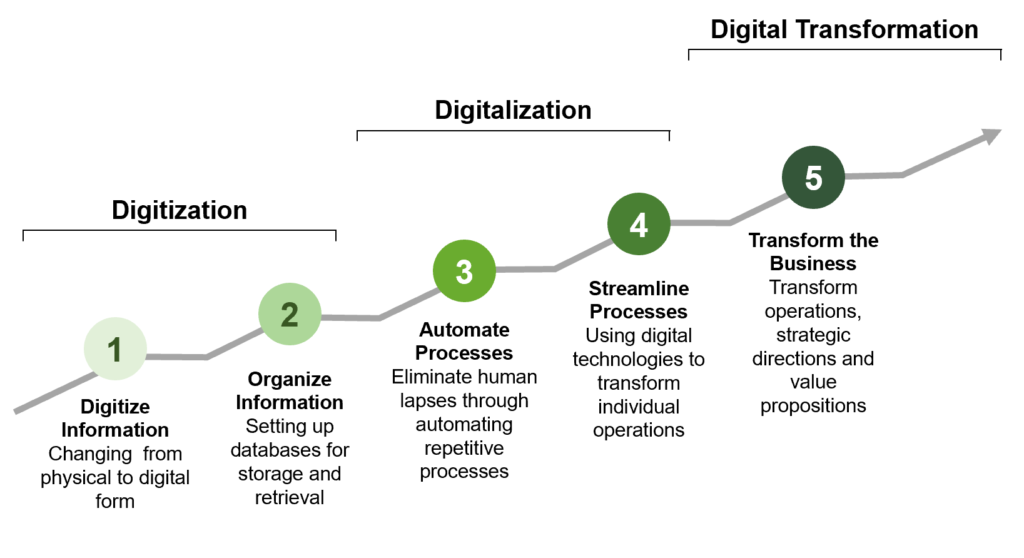

- Workflow Digitalization: Automate processes with low-code/no-code tools for increased efficiency and collaboration.

- Lean Six Sigma: Eliminate inefficiencies and reduce defects with a data-driven approach.

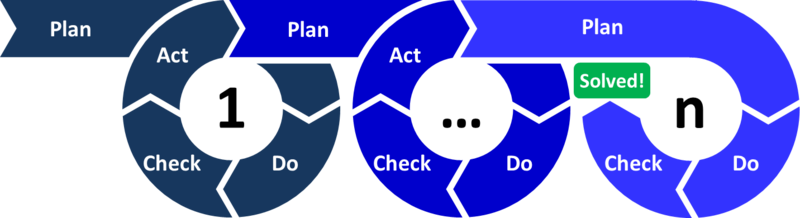

- Kaizen Blitz Events: Rapidly identify and implement process improvements.

- Process Mining: Gain insights into your processes with event log analysis.

- Continuous Improvement: Implement ongoing monitoring and optimization.

- Digital Transformation: Revolutionize your business with strategic technology integration.

Why Choose Me?

- Proven track record of delivering measurable results.

- Expertise in Lean Six Sigma, Kaizen, and process mining.

- Focus on data-driven solutions and continuous improvement.

- Experience with low-code and no-code solutions.

Transform Your Processes Today.

Discover how I can help you achieve operational excellence.

Further reading

Whitepaper Operational Excellence

Whitepaper Operational Excellence

April 2025

Author: Dominik Schweizer

Real-world case study Operational Excellence in Government: A compilation of DOGE tweets (2025)

Potential for Cost-Reducing and Efficiency-Increasing Measures in Financial Institutions

Potential for Cost-Reducing and Efficiency-Increasing Measures in Financial Institutions

KfW-Report No. 3, 2016

Autors: Diana Cazacu, Tatyana Dolgaya, Till Bruckner, Michael Kortenbusch

Warum Robotic Process Automation ein wichtiges Firmenwerkzeug sein kann

LinkedIn Post March 15, 2024

Author: Dominik Schweizer

(archived copy)

Clients and Partners